Frequently Asked Questions

Here are some of the common questions we get:

1. For cabinet painting........ Couldn't I just paint them myself?

Sure you can.

The question is…..will you be happy with them?

And will you have to redo them in a few months because they look bad?

There are several things that can go wrong, such as: peeling, flaking, paint sags, and brush marks.

Additionally, if you have open grain cabinets (such as red oak, or golden oak), the grain needs to be filled with a heavy-duty primer to look right.

These are just some of the things you’ll want to consider.

Additionally, kitchens and bathrooms cabinets are unique because of the amount liquid, grease, food, heat, etc. they are exposed to.

They also have a lot of everyday use, so it’s important the finish will look good for years, not just days or weeks after you complete the job.

For this reason, we have a multi-step process that meets all of KCMA standards to ensure your cabinet’s finish will stand up to these elements over time, and not fall apart (peel, ship, fade) under normal use.

2. How do you prep the cabinets for refinishing?

There are a few critical steps we do on every job to ensure long lasting finishes.

First, we clean the surfaces extensively so that all the oils, dirt, waxes and silicones, etc are eliminated and can’t contaminate the process.

Then we sand with 2 different sanding level grits so the primer can properly adhere (without leaving indentations or swirl marks on the wood).

If either of these steps is skipped, it doesn’t matter what type of paint, or coating you use, the finish will not last, or it will have imperfections (such as scratch, marks, or “orange-peel” blooming in the finish).

So, whether you’re painting your cabinets, or hiring a professional, make sure that the cabinets are thoroughly cleaned & and carefully sanded before any coatings go on them.

To prolong the finish life, we also suggest we installing knobs, pulls or handles if you don’t already have them as that will help extend the life of the paint or clear-coat, as it keeps hand oils from wearing down the finish.

Plus, they’re pretty and add aesthetic value, of course!

The other consideration is time and energy…….if you’re not experienced it will take you MUCH longer to do yourself.

However, if we do it; we’re in and out typically within a week on-site! That way, you can get it done, and get on with your life without your cabinets being a mess for weeks on end.

3. Painting, Refinishing, Refacing, or Replacing........what's the difference between all those?

Painting & Refinishing

When we use the term “cabinet painting”, it always incudes the whole refinishing process.

This means we clean & degrease, sand, and apply 2 coats of primer.

That is followed by our industrial high performance pigmented 1-2k enamel, or conversion varnish (note that we do not use regular paint).

Then we put hardware back on and bring them back to the house to install. The cabinet boxes are sprayed at the house and nothing gets moved excepts the doors and drawers.

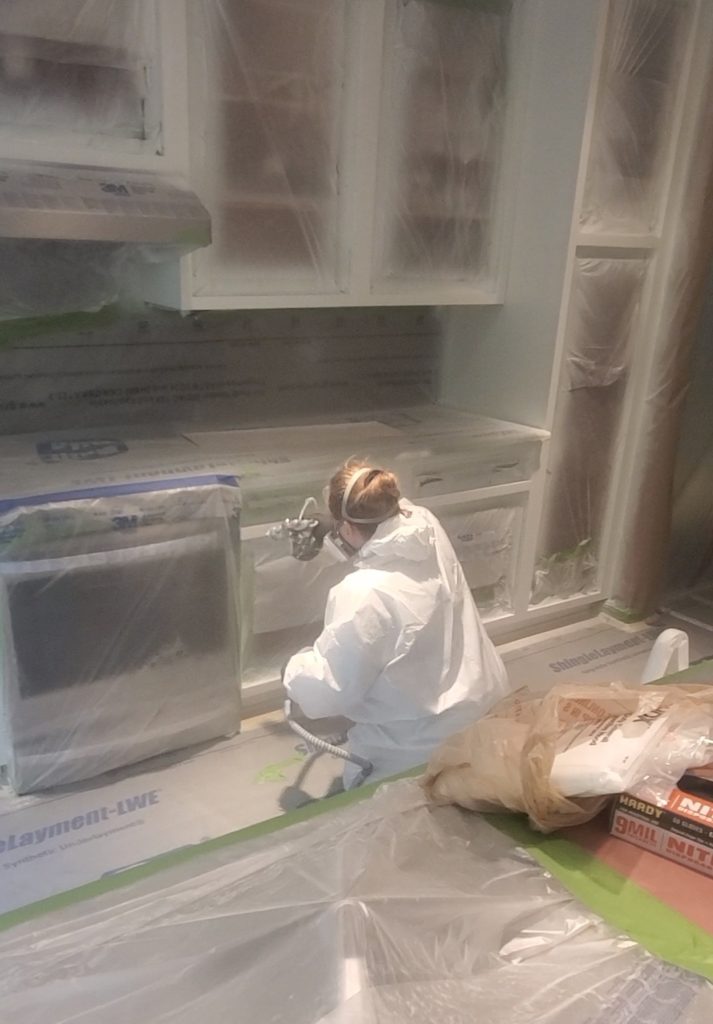

Here's an example of Painting (we call it Refinishing since we use commercial products & processes).

Refacing.....

Now, refacing is something entirely different. “Refacing” is when you change the actual doors & drawer fronts (not just the stain, or color that sits on top of the doors & drawers). It includes the refinishing (painting) for the cabinet boxes, but we make all new door fronts and drawer fronts.

So if you want to update your cabinets to “Shaker” style doors for example, but your cabinet boxes are fine and you like your current layout; just reface! There’s no need for all new cabinets in that scenario.

Example of Refacing: Before, there were these dated pine doors

And after; all new Shaker style doors. Looks like a brand new kitchen!

Replacing.....

Replacing is when you do actual remodeling.

It involves removing plumbing, electrical, typically flooring along with tearing out all your cabinetry and buying new cabinetry to get installed.

This is only needed if you need to change the layout of your kitchen or you have actual damage to the cabinet boxes for example.

How long does it take?

Unlike a typical kitchen renovation, instead of months we are typically done within 2 weeks, even for the larger kitchens!

Here’s what a timeline might look like for small kitchen.

Monday

We spend the day prepping your kitchen by first washing and degreasing your cabinets.

We remove all the doors and drawers and begin masking off all the cabinet boxes and create a controlled spray area that is properly ventilated.

Tuesday

After working at the doors at our shop, we will return to install the doors and drawers, install the hardware and do a final walk through to ensure everything meets your expectations.

Wednesday

We finish any prep work left such as fulling of knots, etc and make sure all surfaces are looking good and smooth; ready for primer.

Thursday

We set up the spray machine, check the color and start with spraying the primer.

Wait for it to dry; sand the primer smooth, fix imperfections and then apply a second coat of primer.

Friday

Now we should be spraying topcoat.

Then we will clean up the masking and plastic and do any necessary touch up on the cabinet rails, stiles and boxes.

The next week

After working at the doors at our shop, we will return to install the doors and drawers, install the hardware and do a final walk through to ensure everything meets your expectations.

What type of finish does Lewis Cabinet Co. use for "cabinet painting"?

Answer: We use Pigmented Conversion Varnish and 1-2K enamel.

When it comes to finishing cabinets and millwork, there are various options available, including paint, stains, and varnishes.

While each has its own advantages, pigmented conversion varnish stands out as a superior option for those looking for exceptional durability and longevity, and that is why it is our product of choice.

What is Pigmented Conversion Varnish?

Pigmented conversion varnish is a type of varnish that contains a high percentage of solids, making it thicker and more durable than traditional lacquers and paints. It is a two-part system that is composed of a resin and a catalyst, which are mixed together just before application. Pigmented conversion varnish is known for its excellent adhesion, chemical resistance, and hardness, making it an ideal choice for high-traffic areas such as cabinets and millwork.

Benefits of Pigmented Conversion Varnish:

- Durability

One of the primary benefits of using pigmented conversion varnish is its durability. It provides a tough, durable finish that can withstand regular wear and tear, making it an ideal option for cabinets and millwork. It is highly resistant to scratches, chipping, and peeling, and can hold up against harsh cleaning agents and chemicals. Whereas lacquer would typically chip if scratched, CV will mold and bend; it has more flex. - Easy Maintenance

Pigmented conversion varnish is also easy to maintain. It can be easily cleaned with soap and water or a mild detergent, and it does not require regular waxing or polishing. This makes it an ideal choice for busy households or commercial settings.

- Enhanced Appearance

Pigmented conversion varnish offers an enhanced appearance, with a smooth, opaque uniform finish that gives a rich solid color. It is available in a vast range of colors, allowing homeowners, contractors and designers the ability to customize the look of cabinets, or millwork to their liking. - Quick Drying Time

Pigmented conversion varnish also has a quick drying time, which means that projects can be completed in a shorter amount of time and touch-ups (if needed) can be done quickly. This is especially important for those who need to finish projects quickly, such as contractors or homeowners with tight deadlines. - Cost-Effective

While pigmented conversion varnish may be more expensive than traditional paints and stains, it is more cost-effective in the long run due to its durability and longevity.

Cabinets and millwork finished with pigmented conversion varnish will last longer than those finished with traditional paints and stains, reducing the need for frequent repairs or replacements.

We believe conversion varnish is the gold standard, and an excellent choice for those looking for a durable, long-lasting finish for their cabinets and millwork.

It’s superior adhesion, chemical resistance, and hardness make it an ideal option for high-traffic areas. Combined with its ease of maintenance, quick dry time, and cost-effectiveness make it a great choice for homeowners and contractors alike.

If you are looking for a finish that will stand the test of time, conversion varnish is a winner!

Is there a Warranty?

Absolutely.

You want to be sure that you’re making the right decision before hiring a cabinet contractor and we understand that.

So you can have total peace-of-mind that not only will we make sure you’re happy with the work, but will do what’s needed if there’s any issues after we leave as well.

That’s why we guarantee our work, and promise to take care of your cabinets as if they were our own!

We offer a 3 year warranty on chips, peeling or any other application issues so you don’t have to worry if it’s going to hold up or last.

We aim to earn your business more than once, and to build a long-lasting relationship so you’ll have someone you can trust for all your cabinet painting, or fine furniture needs in the future.

What forms of payment do you accept?

- Cash (no fee)

- Check (no fee)

- ACH (e-check, has 1% fee)

- CashApp – (no fee)

our tag on there is $LewisCabinet